|

Some basics for bootmen

Boot Terminology |

| Have you ever been confused by some terminology

describing different parts of boots? You're not alone. Here is a

guide to the most frequently used terms and even some esoteric references, too.

Links are in blue. These go to other web pages.

Boot terms are in red. The terms are defined in

the paragraphs below.

|

| |

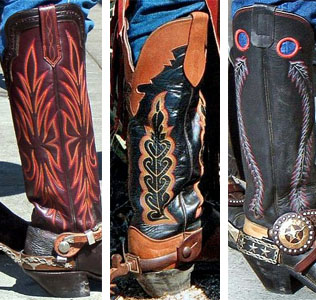

| BOOT SHAFT |

| The Boot Shaft is the part of the boot

that covers your leg. It has two measurements. The height is

taken on the inside seam of the boot, and is measured from where the

shaft meets the sole of the boot, to the top of the shaft. To determine

where the top of a boot will hit on your leg, measure the height of the

shaft against the inside of your leg, starting at your instep. The

circumference (sometimes called

calf size) is the

measurement around widest part of the shaft of the boot. To see if

tall boots will fit your calves, measure around the widest part of

your calf, and compare your measurement to the shaft circumference.

An overlay and inlay are

decorative work involving multiple layers and colors of leather. See the section on

the Upper (Vamp) below for more information on these designs.

A zipper or buckles may

be used on the side or back of a boot shaft to facilitate making a boot easier to put

on or take off.

A liner (or lining) may be sewn on the inside of the

shaft for added strength and stiffness, as well as to increase water resistance.

Liners on the inside of boot shafts are usually made of soft cowhide leather.

But some liners for boots like Mukluks

may be made of fur or synthetic materials. Some German Air Force

Knobelbecher Boots had a shearling lining,

which is processed soft sheep wool. A drawback of lined boot shafts is that the

lining can limit moisture from leaving the boot.

A back stay is a strip of leather that runs up and

down the back of the inside of the boot lining to stiffen and support the boot

and hold up the top, which gets the most movement.

Shafts on boots like cowboy boots may also

have fancy stitching of various and contrasting colors

sewn into the shaft. Such stitching makes boots very distinctive. Some particular

brands of cowboy boots use stitching patterns unique to them which some discerning

Bootmen can distinguish.

Piping is a rounded strip of leather that runs up

the side seams of some types of boots. Sewn dead center between the back and

front of the boot, piping can be in the same color or a contrasting color of

leather to make the boot or its stitching patterns stand out more. Piping is also

used to hide stitching that holds the side seams together.

Boot shafts are finished differently at the top:

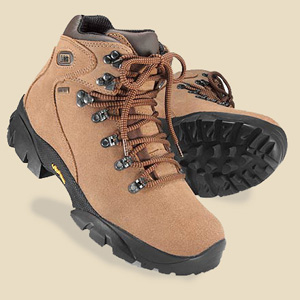

Hiking and work boots may have a padded collar that

cushions the ankle and the Achilles tendon. The collar limits rocks and mud from

entering the boot while hiking on rocky terrain.

Other boots finish the top of the boot shaft in what is called a

scallop. A scallop can be flat, called a stovepipe because

the boot shaft looks like an old-fashioned stovepipe.

Biker Boots usually have a stovepipe

scallop. Cowboy Boots often have a v-shaped

(sometimes called a dip) or other

type of scallop. There are as many as eight different types

of shaft scallops on boots.

Scallops may be finished with beading, which is a

slender, rounded strip of leather that encircles the top of the boot. The beading

is most often made from the same material as the piping that runs down the side of

the boot.

Some pull-on boot shafts may have features to help the wearer pull the

boot on. These include:

- A pull tab is usually a strip of

leather stitched around the left and right side of the shaft. A pull tab may be

the same color as the shaft color, or a contrasting color.

- Mule ears are longer strips of leather that look

like the ears of a mule. These are found on some

cowboy boots like buckaroos.

- Shaft holes are just what their name says -- two

holes near the top of the right and left side of the boot shaft. Buckaroo cowboy

boots often have shaft holes.

- Inner pulls are usually made of synthetic fabric

and are sewn inside the right and left sides of a boot shaft, such as on a pair of

police patrol boots. A Bootman will often

use a pair of boot hooks to grab each inner pull to

pull the boot on, especially if boots will be worn over pants such as breeches.

|

| |

| UPPER (VAMP), TOE BOX, TONGUE, AND KILTY |

|

The upper, also called a vamp, surrounds and

protects the foot from the sole up. Uppers are built around a

last, which is a mold used to shape the boot's materials.

Some boots are made with a single layer of material (single vamp),

a double layer (double vamp), or even triple layer (triple vamp) for added insulation and water penetration resistance.

The upper attaches to the heel counter in the back, and to

the front parts of the boot top in the front.

Other components of the upper may include the parts listed below,

but these parts are not on all types of boots.

The toe, described in the section about boot toes

below.

The heel box, described in the section about boot

heels below.

An overlay and inlay are

decorative work involving multiple layers and colors of leather. These may be overlaid

or underlaid. Overlay patterns are sewn over the principal boot leather (overlaid),

while inlay patterns are sewn in from underneath (underlaid) to produce a cutout

window-type design. Overlays and inlays may be on the upper (vamp) and on the boot

shaft.

A specialized type of overlay is a motorcycle shift guard

which is an added layer of leather sewn on to the upper of the left boot of a pair of

some brands of biker boots. The shift guard is

designed to provide protection to the boot and the foot of a motorcycle rider who

uses a foot-operated shift lever on the left side of a motorcycle.

A liner built into the upper to increase water

repellency. Liners may be used on boots with fabric uppers, like

hiking boots. The drawback of liners is

that they can limit moisture from leaving the boot.

The tongue folds under boots with the laces when tied.

A fully gusseted tongue joins the tongue to the leather body via

flexible leather, keeping water and dirt out of the boot.

A kilty or false tongue

is an 8" (20 cm) strip of leather with a serrated edge at the bottom which is held in

place by the bootlace as it passes through the bottom eyelets. Kilties were

originally intended to provide padding between the bootlaces and the instep of the

foot in logger boots. This was necessary in

boots which used thin leather for the tongue and also protected the tongue from wear

by the laces.

|

| |

| BOOT TOES |

|

| The boot toe is the very front

end of the boot. Toes can come in as many as

12 different styles,

varying from ultra narrow (X-toe) to wide and round (W-toe). The most variation in

boot toes are found on cowboy boots.

Here are other features of boot toes:

The toe box surrounds and protects the wearer's toes.

It is a stiff piece of material that is placed in the top of the boot toe between

the outer vamp leather and the lining to reinforce the shape. The heavier the boot

weight, the more protection.

A steel toe is a piece of steel molded on the inside

of the boot's toe box, usually between two pieces of leather in a double-vamp boot.

A steel toe provides reinforcement and protection to the wearer's feet.

A toe rand, also known as a

toe cap, is an optional piece of metal nailed on to the

front toe of a cowboy boot. Toe rands or caps are added for appearance and styling.

They may be made of various metals such as aluminum, silver, or gold, or metal alloys.

A toe bug is a design stitched onto the top of the

vamp of many cowboy boots so you can see it when

you look down at the boot.

A wingtip is on some

cowboy boots, and is usually a contrasting color of

leather found at the toe. A wingtip usually is in a V-pattern and looks like the edge

of a bird's wing.

|

| |

| HEEL, COUNTER, HEEL LIFT, AND SPUR RIDGE |

|

Boot heels are specially designed for

a particular type of boot. Cowboy Boots can have

as many as 13 different

types of heels, ranging from low, flat, short block heels to 3" or higher

underslung heels. Other boots usually have a heel

that matches the style of the boot. For example,

engineer boots usually have a rounded

block heel of about 1" - 2", usually finished with a

rubber heel lift on the bottom.

Hiking boots usually have the heel integrated

with the rest of the boot sole and has little difference in height from the rest

of the sole.

Other parts of a boot related to the heel include:

The heel cup, or heel counter,

that holds and supports the heel, assisting in minimizing lift when walking and

offers ankle stability.

A heel lift is a protective cap or pad, usually made

of rubber, attached to the bottom of the heel on most (but not all) boots. Heel lifts

are usually from 1/8" to 1/4" in thickness.

Taps are sometimes found on boots. A horseshoe tap may be used on the heel, and a

rounded tap may be used on the sole at the toe.

The purpose of taps on boots is to prevent wear, and they're also used for sound,

so that the Bootman can be heard walking in his boots.

A heel pad is a thin piece of leather that is glued on

the inside of the boot, on top of the insole. It protects the insole at the heel

from excessive wear.

A spur ridge is a small "ledge" or part of a boot heel

that sticks out behind the bottom of the boot shaft onto which a spur may be worn.

The ridge helps to prevent the spur from falling below the heel, especially when

mounting or dismounting a horse.

A heel rand, also known as a

heel cap, is an optional piece of metal nailed on to the

back of the boot where the heel meets the bottom of the boot. Heel rands or caps

are added for appearance and styling, usually on cowboy boots. They may be made of

various metals, such as aluminum, silver, or gold, or metal alloys.

|

| |

| BOOT SOLES |

|

The boot sole is the only part of the boot

besides the bottom of the heel that actually has contact with the ground. As such,

boot soles are usually made of very sturdy materials that can withstand constant

wear and tear, and will not be easily penetrated by debris on the ground.

A boot sole is composed of three parts:

The outsole which is the part that touches the ground.

Outsoles may be made of leather, rubber, or synthetic materials.

- Leather soles are usually found on

cowboy boots and boots like those built on the Wellington design. The leather is

usually thick and smooth. New boots with leather soles may slide on carpet or

polished floors. Leather soles make for a dressy appearance.

- Rubber soles are found on boots used by bikers and hikers,

among others. Boots with rubber soles provide good traction and resistance to

penetration by rocks or road debris.

- Lug soles are made from a special type of hard,

durable rubber. One particular and highly popular type of lug sole is called a

Vibram® sole. This is a lug sole with a particular

tread pattern and diamond-shaped sole insert. Lug soles provide superb traction.

- Waffle soles may be found on

hiking or

combat boots. They are also made of leather,

but the pattern is crossed like a waffle. These soles resist accumulating

dirt or mud between the treads.

The midsole is a layer of synthetic, leather,

or fabric material that stabilizes the boot and supports the foot with shanks.

A shank is a metal or heavy plastic strip in the sole

used as reinforcement for the wearer's arch. It provides support for the bottom

of the boot. A full shank goes to the toe while a 3/4 shank goes to the

ball of the foot. Shanks can be plastic or steel. Most bootmakers today

use a thin, precut strip of eighteen-gauge steel, which is glued,

whipstitched, or tacked in place.

The insole directly contacts and cushions

the foot inside the boot and is often removable. Insoles are usually made

of a soft synthetic material, or may be made of leather, fur, or wool.

Sometimes Bootmen have complained about their feet hurting inside boots.

Replacing the original insole with a new one may relieve that problem,

particularly if a new type of insole is used such as one with gel inserts.

Boot soles are attached to the upper with either stitching or glue.

Stitching provides stiffness to the boot. Stitching also allows worn soles

to be replaced easily. Gluing, or cementing, soles to the upper is not as

durable as stitching, but is less heavy and more flexible.

In hiking boots, a piece of rubber covering

the joint between the upper and the boot sole is called a

rand. It is not the same thing as a heel or toe rand

on a cowboy boot, but has the same shape. A rand protects the joint between the

upper and the boot sole and has a tight seal to ensure water resistance.

Welt or welting is a strip of heavy leather that is

sewn around the lasting space of the upper and joins it to the insole. The sole is

then stitched to the welt with a second seam. The welt is also known as the "rand"

in cowboy and many other styles of boots. Inseaming thread

(a waxed flax or polyester thread which will lock in position when stitched tight)

is used to stitch the welt to the upper and the sole of the boot.

A pegged sole has wooden pegs made from maple or

lemonwood driven through undersized holes, completely piercing the outsole, upper

and insole. Then the pegs are floated (smoothed) off on the interior of the boot.

These pegs, in rows of one to three deep, run along the arch (shank) of the boot

down to the heel. Along with stitching and glue, they hold the insole and

outsole together. Pegs are usually a sign of a better-quality boot. If a

boot sole is pegged, one can see the tops of the pegs when looking inside

the boot.

|

| |

|

Content from Booted Harleydude. Pictures from DaveM,

Booted Harleydude,

Big Black Boots, and

Champion Attitude Boots. These are used

with permission. A few other pictures are from various publicly available internet

sources.

Text from About.com/Shoes,

Bass Pro Shops,

Champion

Attitude Boots, and the internet article titled

How a Cowboy

Boot is made. Specifics referenced in the latter internet page use

references from two books: The Art of the Boot and The Cowboy

Boot Book by Mr. Tyler Beard from which content on this page is quoted.

|

Tutorial - Types of Boots

Boot Information Resources

Boot Information Page Index

|